Manufacturer of Direct Orange S

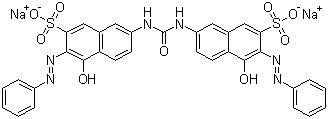

Molecular structure:

| Color Shade |

Product Name |

Content | Dyeing Depth (%o.w.f) |

Fastness Properties(Change of Shade) | |||||

| Light | Washing 40℃ |

Hot Pressing 200℃ |

Perspiration | Rubbing (Dry) |

Rubbing (Wet) |

||||

|

|

Direct Orange S | 150% | 3.0 | 3 | 4 | 4-5 | 4 | 4-5 | 3-4 |

Synonyms: C.I. 29150; C.I. Direct Orange 26; C.I. Direct Orange 26 (VAN); C.I. Direct Orange 26 disodium salt; C.I. Direct Orange 26, disodium salt (8CI); DIRECT ORANG 26; disodium (3E)-4-oxo-7-({[(6E)-5-oxo-6-(2-phenylhydrazinylidene)-7-sulfonato-5,6-dihydronaphthalen-2-yl]carbamoyl}amino)-3-(2-phenylhydrazinylidene)-3,4-dihydronaphthalene-2-sulfonate

Property: Golden powder. The water solubility is general, and it is sensitive to hard water. The aqueous solution is red orange and orange brown with concentrated alkali; Add dilute alkali and turn slightly yellow. Slightly soluble in ethanol, golden orange. It is bright red in concentrated sulfuric acid and produces red light orange to red precipitation after dilution; There are dark yellow precipitates in concentrated nitric acid.

Application:Direct orange S is used to dye cotton and viscose fiber to get red orange, which has poor migration, is sensitive to salt and has good dye uptake. It is also used for direct printing of cotton and viscose fabrics, especially viscose fabrics. It can be used alone or combined with yellow, red, gray, brown and other colors to adjust color light and increase chromatography. It can also be used for dyeing silk, wool, vinylon and nylon and direct printing of silk fabrics.

Storage:store in a cool and ventilated room.

Quality guarantee period: 36 months.

Packing: 25kgs iron drum or woven bag.